How to Maintain Gel Batteries for Industrial Applications | MHB Battery

Gel batteries, a type of Valve-Regulated Lead Acid (Vrla) battery, are widely used in solar energy storage, UPS backup, telecom systems, and other industrial applications. Known for their long service life and stable deep-cycle performance, gel batteries are often described as maintenance-free. However, proper use and routine inspection are still essential to maximize performance and lifespan.

As a professional gel battery manufacturer,MHB Battery provides the following guide to help users maintain gel batteries effectively in demanding environments.

1. What Makes Gel Batteries Unique

Gel batteries use a silica-based electrolyte that turns into a thick gel. This design offers several advantages over flooded or Agm Batteries:

-

Strong resistance to deep discharges

-

Superior performance at high temperatures

-

No leakage or electrolyte stratification

-

Suitable for cyclic and standby applications

MHB deep-cycle gel batteries are designed with long service life in mind, supporting up to 12 years in float conditions when properly maintained.

2. Recommended Gel Battery Maintenance Practices

Although sealed and maintenance-free in structure, gel batteries still benefit from proper handling:

Initial Charging

-

Use a compatible charger for VRLA/gel batteries

-

Avoid overcharging during first use

-

Fully charge the battery before putting it into service

Voltage Regulation

-

Maintain float voltage between 13.5 and 13.8 volts (for 12V systems)

-

Avoid charge voltages exceeding 14.1 to 14.4 volts

-

Use smart chargers or voltage regulators to avoid overcharge

Temperature Control

-

Ideal operating range: 20 to 25 degrees Celsius

-

High temperatures accelerate battery aging

-

Install ventilation and thermal monitoring in battery cabinets

Discharge Management

-

Avoid discharging below 10.5V for 12V batteries

-

Limit depth of discharge to extend cycle life

-

Use a low-voltage cutoff system when possible

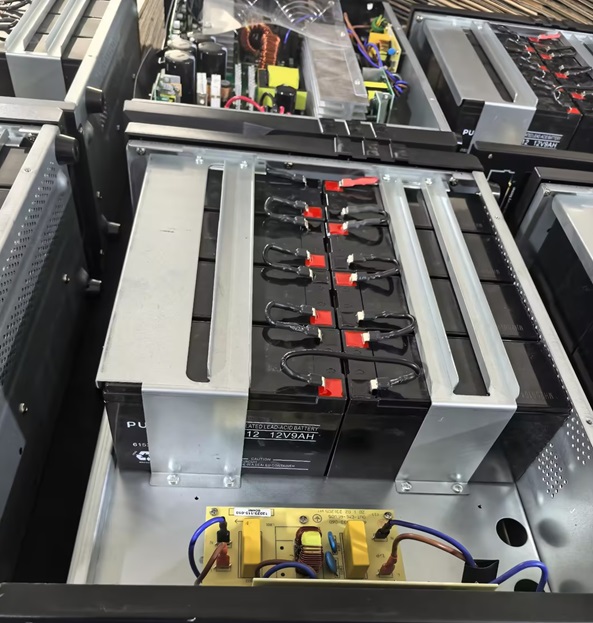

Visual Inspection

-

Check for cracks, bulging, or deformation

-

Inspect terminals for corrosion or loose connections

-

Ensure battery cases are clean and dry

Electrical Connections

-

Keep connections tight and clean

-

Monitor torque settings and re-tighten if necessary

-

Use anti-oxidation grease in harsh environments

3. Common Gel Battery Mistakes to Avoid

-

Using incompatible AGM or flooded-type chargers

-

Fully discharging batteries before recharging

-

Ignoring ambient temperature in battery enclosures

-

Storing batteries in unventilated or humid areas

4. MHB Battery's Quality Commitment

MHB gel batteries are manufactured using high-purity lead, advanced silica gel electrolyte, and separators sourced from reliable suppliers such as Yuguang, Sinoma, and Juhe. Our production follows strict quality control processes to ensure performance, consistency, and safety.

Key Features:

-

Excellent deep-cycle durability

-

Long standby life

-

Leak-proof sealed construction

-

OEM and export-ready with CE, UL, ISO, and ROHS certifications

5. Serving Global Industrial Needs

With over 30 years of experience, MHB Battery supplies gel batteries for:

-

Solar and renewable energy storage

-

UPS systems and emergency power backup

-

Telecom and grid-connected battery banks

-

Industrial and commercial power systems

Our gel batteries are trusted by partners in over 40 countries for their reliability and quality.